1-DAY COATING SYSTEMS: HERE’S THE REAL TRUTH

In August 2020, GarageFloorCoating.com published an insightful article that explores the potential dangers associated with “1-day” coating systems (Polyurea-Polyaspartic One-Day Systems: Do They Work). These garage floor coatings have grown in popularity due to their quick and easy installation process favored by contractors. And clients appreciate the convenience of having their project finished within a day. However, it is important to remember the old sayings “Haste makes waste” and “Buyer beware”. Think about this: how often does haste (in this case, installing a concrete coating system in 1 day) equate to quality where contractors are concerned?

What’s a Polyaspartic?

Widely utilized across concrete industry sectors, polyaspartic coatings are known for their rapid curing properties. They offer exceptional resistance against UV rays, chemicals and impacts once applied. Furthermore, a high-quality polyurea-polyaspartic coat can effectively prohibit tire marks from staining your concrete (we specify “high-quality” because there are a lot of low quality polyurea-polyaspartic coatings out there). This type of coating can serve as a long-lasting clear topcoat.

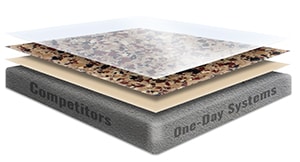

However, one significant drawback is that polyurea-polyaspartics do not bond well under damp conditions — making them unsuited as primer coats directly on concrete surfaces (due to their chemical nature, polyureas cannot be applied thickly, and thus cannot withstand high moisture/hydrostatic pressures). This constraint can be easily bypassed by applying a moisture-mitigating epoxy as a primer layer. Epoxy can be applied very thickly, due to the way in which it cures, before applying the polyurea-polyaspartic as its transparent finishing layers. Although this method requires more time (because epoxies cure slower) – typically up to 2 days instead of 1 – seasoned professionals (and architects) will attest to this method of application.

It’s worth mentioning that contractors who promote “1-day” applications may attempt to devalue epoxy products (as part of their sales presentation), yet include a warranty exclusion in their contractual agreements against “moisture-related issues”. Expert installers understand that all types of coating products, like epoxies, urethanes and polyurea-polyaspartics, come with distinct pros-and-cons. Reliable contractors installing commercial-grade flooring apply coating systems with mixed coating types to produce the best and longest-lasting concrete flooring.

Why aren’t “1-Day” systems covering moisture-related concerns?

Applying thin coats of polyurea (or polyaspartic; contractors use both names as a polyaspartic is simply an “aliphatic polyurea”) directly on concrete, as is done with “1-day” polyurea-polyaspartic coating systems, is ill-advised due to delamination (peeling) that can occur over time in medium-to-high moisture vapor transmission scenarios. And all concrete has moisture. Contractors choose this method as it lessens product and labor costs, thereby boosting profitability (in their favor). However, their warranties don’t cover high-moisture issues or potential issues with tire staining (also called plasticizer migration). It’s in their small print! With these constraints in mind, why would you ever invest in a “1-day” coating system? Clearly, haste makes waste.

How do We Differ?

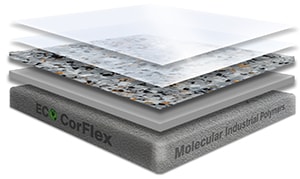

Our garage floor coatings come secured with guarantees protecting against moisture, tire staining and most auto fluids exposure. After preparing the concrete (grinding with propane grinders), we apply a thick, moisture-mitigating epoxy primer (not a polyurea), then chip into the wet primer, and top it all off with dual, top-grade (100%-solids) polyurea-polyaspartic clear coats in all our garages. This ensures maximum safeguarding of your concrete coating. Albeit, the process takes longer! Proudly, it takes 2 days…not 1. Quality takes time.

In addition, several of our full-chip concrete coating series contrast competitors’ offerings due to our unique mica stone infusedchip blends. Unlike others who utilize thermoplastic chips only, we offer thicker, stronger, and more aesthetically-pleasing mica flake flooring. Our Earth Effects, Bagari SE and Vintage Mica series feature an ultra-thick, 100%-solids epoxy primer coat designed to mitigate for moisture, a full-flake, mica infused broadcast, plus two 100%-solids polyaspartic topcoats equipped with anti-skid, resulting in a total thickness exceeding than 35 mils for our garage floor coatings. Because of this, we proudly and confidently provide warranty coverage against the leading causes of coating system failures: moisture-related problems and hot tire pickup.

For those seeking visually impressive, industrial-strength concrete flooring with a real guarantee, ask us about our full-chip garage floor coating options. Call us now or click here to get your free quote so we can present you with the best available solutions for your garage flooring and other concrete spaces.