In New York, where the climate ranges from hot, humid summers to icy winters, ensuring your garage floor is well-prepared is essential for durability and aesthetics. Imagine trying to build a sturdy house on an unstable foundation; without proper concrete preparation, your epoxy coating won’t last. Properly prepping your concrete floor is crucial if you want a garage floor that’ll last.

What’s a Concrete Surface Profile?

The texture of the concrete surface, known as Concrete Surface Profile (CSP), is a key factor in the success of an epoxy coating. For the epoxy to bond effectively, the concrete needs to have a roughness level of at least CSP 3. Techniques like low-pressure water jetting, acid etching, mechanical scarification, and chemical strippers often produce CSPs below 2, which are insufficient for long-term adhesion and can lead to peeling.

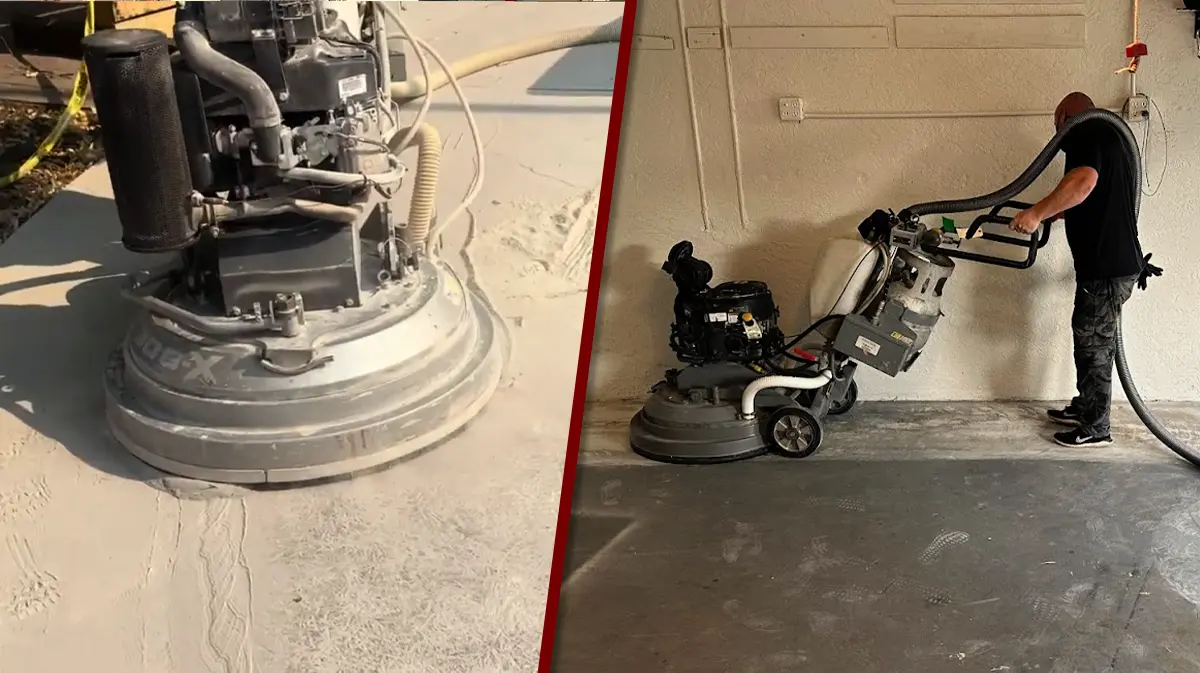

In contrast, methods like sandblasting and rotomilling can create a CSP above 4, which is too rough for most residential applications. Grinding is the preferred method, achieving a CSP between 3 and 4, which is ideal for epoxy coatings.

Why a Grinder?

Propane grinders are particularly effective for this task. They offer greater power and efficiency compared to electric grinders, although they come with a higher initial cost. However, propane grinders save on labor and time, making them a cost-effective choice in the long run. They are also safer for indoor use, as they don’t require electricity, reducing the risk of electrical hazards in damp conditions, and they emit near-zero exhaust, making them suitable for indoor environments.

Can’t I Just Do It Myself?

Many DIY epoxy coating projects fall short due to inadequate concrete preparation. The specialized equipment required to achieve the proper CSP is typically too costly for most DIYers. Professional contractors bring the necessary expertise and tools to ensure the concrete is prepared correctly, resulting in a high-quality, durable epoxy coating. In New York, where the weather can be particularly challenging, proper preparation is vital to maintain the integrity and appearance of your garage floor.

Investing in professional services for concrete preparation and epoxy coating ensures your garage floor withstands New York’s climate challenges. Properly prepared concrete provides the needed profile for the subsequent application of the moisture-mitigating epoxy. This results in the most durable finish. Professionals understand the local conditions and apply their knowledge to deliver superior results.

We’d be remiss if we also didn’t mention: Adhering to local building codes in New York is also extremely important when preparing your garage floor. These regulations ensure that installations meet safety and durability standards. Professional contractors are well-versed in these requirements and can ensure your garage floor complies with all necessary codes, enhancing your property’s value and safety.